DRIVE-IN & DRIVE-THROUGH RACKS

High weight-carrying capacity

Mechanical durability

Variability

Safety

Fast installation

-

Pallets are loaded on special rails. These rails, i.e., loading beams, are made from bent galvanized steel sheeting.

-

The steel rails are either single- or double-sided and are bolted to the upright frames.

-

Drive-in racks also contain a portal support beam located at the top of the upright frame to guarantee the frames' rigidity.

-

There are vertical and horizontal bracing rods to ensure the stability of the drive-in rack.

-

When designing the configuration of a drive-in rack, it is important to know the type of forklift to be used.

-

It is possible to supplement the drive-in rack setup with racking accessories, e.g., forklift guides, upright protectors, pallet backstops for the far end of the lane, etc.

Suitable for freezer rooms

High storage density

EU Compliant

Easy to operate

Variants of pallet racks

Palet Racks - Basic

Palet Racks - Basic

MOBILE PALLET RACKS

MOBILE PALLET RACKS

FLOW PALLET RACKS

FLOW PALLET RACKS

E-SHOP

Take advantage of our range of products in the PROMAN e-shop. Choose basic pallet and shelf racks. You can configure the cantilever rack according to the load/dimensions to your requirements. The system will automatically generate a quote for you. At the same time, you will find a wide range of accessories for pallet and shelf racks in the e-shop.

Technical Details

-

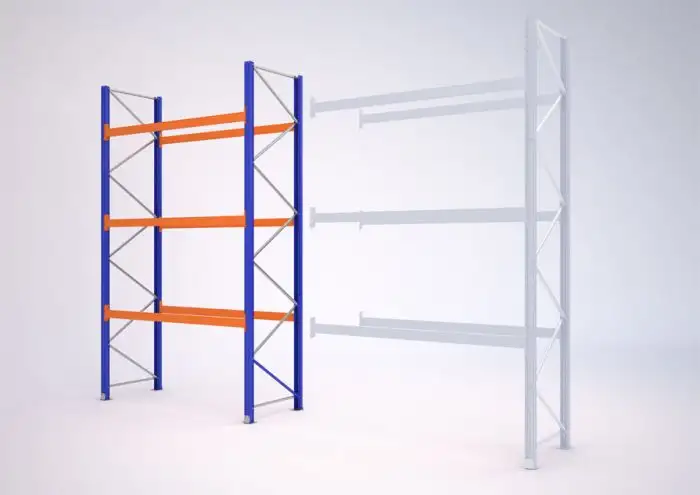

Pallet racks construction

The pallet rack is constructed so that it uses storage space effectively, increases the capacity of warehouse storage areas, and contributes to the clear organization of the material and goods stored. Generally, pallet rack construction is used for storing pallets with material directly on the rack's support beams or on its crossbeams. Barrels, rolls of material, and bundles of sheet metal or boards are stored on specialized crossbeams. Smaller-scale materials or boxes are stored on the decking of the pallet rack's bay. The decking can be manufactured from particle board in various thicknesses, steel grating, panels, etc. The racking quote is provided for the customer according to their requirements. It is common to have single row pallet racking around the perimeter of the warehouse and double row racking in the middle. The aisle width between the racks is determined by the type of forklift that the customer will be using in the warehouse.

-

Technical details

- The racking frame is composed of two uprights connected by the vertical and horizontal diagonals. The diagonals are constructed from rolled steel with a C cross section and are fixed to the uprights with bolts. The racking depth is determined by the length of the cross brace.

- The frame uprights are made of cold-rolled profiles. The upright profile is 100 mm wide and is made of from sheets of thickness 1.5, 2, 2.5 and 3 mm according to the load capacity required. We produce frames in standard heights.

- The frame is perforated with holes 70 mm apart.

- The upright is equipped with a metal footplate that serves to distribute stress and anchor the rack to the floor.

- The uprights are either provided in standard RAL 5010 blue or, alternatively, galvanized.

- The racks are made to be installed on high-quality concrete flooring; any irregularities are compensated for by shims under the frame footplates. After being adjusted, the rack is anchored to the floor using bolts.

- It is customary for racks to be labeled with safety charts for load capacity.

- The depth of the frame is determined by the size of the pallets used; standard sizes are 1100, 900, and 750 mm.

- Double row racking is connected by a spacer to provide the racking with greater stability.

- Passageways for people or vehicles are equipped with decking from particle board or grating to protect against goods falling from the pallets.

- The rack's beams are manufactured from C-sections that has been hot rolled together to create a hollow profile with a rectangular cross section. Special L-shaped steel brackets (left and right) are welded on to both ends. The brackets have angled rectangular pins, which are used to attach the beams to the vertical frame. The beam is always secured by one specially shaped safety catch inside each bracket that protects the beam from falling during pallet handling. Attachment without bolts allows for fast and easy installation.

- The size of the beam section is determined by the bay's required load-bearing capacity and the length of the beam. Standard beam lengths are divided into two series: 1800, 2700, and 3600 mm for Euro-pallets with 2200 and 3300 mm for industrial pallets (i.e., the actual storage length of the beam). The permitted load capacity of the beams is listed in the load capacity chart.

- The pallet is loaded onto the beams at a depth of 1200 mm (Euro-pallets). Other types of loading are resolved on an individual basis using various braces for the pallets.

- The standard color for the beams is RAL 2004 orange.

- The height can be adjusted along the frame at 70 mm increments.

- According to the customer's needs, it is possible to supplement the racking with shelving – from particle board, steel grating, or sheet metal panels, for example. The pallet rack also offers the option of storing reels and rolls on an axle set onto the rack by using special crossbars.

Optional Fittings

- Corner protectors

- Frame protectors

- Racking side protectors

- Labels for storage locations and racking aisles

- Lateral guides for three-way forklifts

- Crossbeams for pallets and barrels

- Mesh or sheet metal wall panels for the racking

- Protection against pallet protrusion

- Transfer stations

- Panels from metal grating (decking)

- Particle board panels (decking)

- Sheet metal panels (decking)

- Sheet metal for load distribution

-

Pallet racks accessories

Racking Protectors

The rack's front side, corners, and uprights are all exposed to damage during forklift manipulation; therefore, we recommend equipping them with protective elements such as upright, frame, and frontal protectors.

Backstops – Protection Against Falling Pallets

We recommend supplementing single row racking with a backstop on the back side – as protection against pallets being pushed off the back side of the rack. It is also possible to cover the whole back side with wire mesh.

Crossbeams

Various types of crossbeams are used as pallet braces when loading box pallets, atypical pallets, or barrels.

Preparation Stations

It is possible to add preparation stations to the face of the racking, where they can be used to prepare the pallet for storage.

Forklift Guides

With the customer's agreement, it is possible to supplement the racking with forklift guides corresponding to the type of forklift used in order to make the racking faster and easier to use.

Decking

According to the customer’s needs, it is possible to equip the racking with decking from particle board, metal grating, or sheet metal panels.

Load Capacity Labels

In a visible place at the end of each row, each rack is labeled with a tag showing the number of storage levels, load capacity of the storage level, and the load capacity of the entire rack.

Bracing

Bracing is used on pallet racking in order to increase the racks' load-bearing capacity and to ensure stability in seismically unstable areas.

-

Download

Photogallery

Why choose PROMAN

Complete Supply from the Proposal to the Installation and the following Service

We provide our customers with the offer including draft of the racking solution for free.

Professional Service in Czech Republic and Abroad

PROMAN s.r.o. is one of the most distinguished suppliers of all types of racking systems on the market and is able to respond in a very flexible way to any and all of a client’s needs.

Our Experience Guarantees your Satisfaction

During that time we have made a trunover of more than 40 bilions of Czech crowns.